Material Handling and Hoisting

Material Lifting Equipment

Material lifting equipment describes a range of products used for lifting and moving goods in a more efficient and safe way over doing it by hand. Industrial Tool Supply has years of experience with lifting equipment. Lifting products include lever hoists, chain hoists, hand winches, clamps, trolleys, and davit cranes.

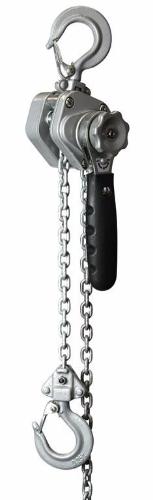

Lever Hoists:

A Lever Hoist is a type of lifting equipment used to lift and lower heavy loads without requiring a machine to lift the item. Lever hoists have a unique advantage over chain hoists in that they can lift objects vertically and pull objects horizontally. The lever hoist commonly uses a safety hook to secure the load and a top swivel connection allowing easy lifting from all angles. The lever controls how much chain is released or retracted thus lifting or lowering the load. To start lifting, crank the lever until the load is lifted into place and to lower move the ratchet lever downward then crank to lower the load.

The mechanical lever hoists available from Industrial Tool Supply are manufactured from lightweight robust materials allowing the hoist to be mounted easily. The lever hoists are easy to operate and require minimum effort to lift the product’s weight load limit (WLL). The mechanical lever hoists are used worldwide in construction workplaces and warehouses. The lever hoist features a selector switch to raise a load, lower a load, or put the hoist lever in neutral for quick rigging jobs. The lever hoists include alloy hooks made of forged steel, a stainless steel ID tag with load rating information, a shroud that acts as a chain guide, and a tag that keeps the chain clean. The chain is zinc-plated so there is no oil on the chain, which will help to keep the mechanism clean and clear of debris.

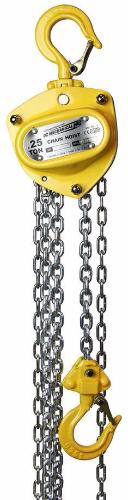

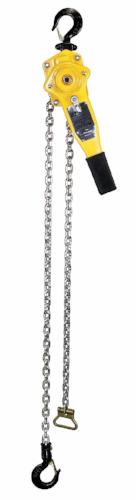

Chain Hoists:

A chain hoist is a lifting device used for lifting or lowering a load by a chain wrapped around a load wheel. The load is attached to the hoist by means of a lifting hook. Chain hoists use a loop of operating chain that one pulls through the block which activates the block to take up the main lifting chain. The lift chain is far larger than the lift wheel over which the chain may function. Therefore, a high-performance chain hoist may be significantly smaller in physical size than a wire rope hoist rated at the same working load.

Selecting the Right Hoist for the Job:

- Look for units with Overload Protection:This feature will not allow the hoist to operate if the unit is overloaded by weight, protecting the operator and the cargo.

- Unique Hand Wheel Design:Enables the hand chain to feed directly into the wheel sprocket from many directions and angles. Thus, the operator can use the hoist while standing to the side of, or above the load without fear of the hand chain jamming.

- Fully Enclosed Gearing:This protects the gears from contamination and debris.

- All Steel Construction: These hoists are strong, durable and rugged, providing a long and dependable service life.

- Forged Alloy Steel Hooks with Cast Steel Safety Latches:Each cast steel safety latch has a bolt and lock nut connection rather than roller pins that facilitates easy latch changing in the field.

Beam Trolleys and Clamps:

Beam clamps and trolleys are hardware designed to suspend or secure fixtures to the I-Beams in a factory or warehouse.

The Beam Clamp: Is designed to provide a stationary fixed point for fixtures, wires and more when tightened down to the I-Beam and can be easily removed by releasing the tightening mechanism.

Beam Trolleys: Are also designed to hold fixtures and wires on an I-Beam. They use wheels to traverse the beam so that although the fixture is attached to the I-Beam the trolley can move like a crane across the beam length.

Trolley Clamp Combo: Is basically a trolley with an additional clamp allowing the unit to move across a beam like a trolley but also has a clamp that can be tightened so it doesn't move.

What to Look For In a Beam Trolley or Clamp!

- All steel construction

- Safety handle lock

- Durable baked enamel paint protection

- Precision ball bearing trolley wheels

- Adjustable to many beam types

Brake Winches: A break winch is a specific type of winch that provides an automatic locking feature allowing the winch to raise or lower a load with better control over a pulling winch. A pulling winch is great for raising an object but is hard to lower one because the winch lock must be fully released. This applies all the weight of the object onto the crank. When unlocked the crank is free-wheeling and great pressure must be used to control the crank from spinning freely. A break winch automatically locks into position and can rise by cranking clockwise or lower and object cranking counterclockwise and when the cranking stops the load stops without the issue of a full release of the break.

Selection of Brake Winches:

Industrial Tool Supply offers several brake winches. There is a carbon steel brake winch and a type 304 stainless steel brake winch for harsh environments where corrosion resistance is important. We also carry an electric winch with a break. All of our brake winches offer the following features:

- All steel construction

- Ergonomic rubber handle

- Multiple frame mounting positions

- Fully enclosed gearing

- Solid machined gear

- Automatic weatherproof Weston brake

- Dual cable anchor point

- Large diameter drum

- Rubber handle

- High gear ratio

- Test certificate & serial number

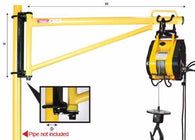

Davit Cranes: A davit crane is commonly used on a ship to load and unload cargo. It is a unique material lifting device that allows the cargo to be lifted vertically and then pivot to move the cargo horizontally and then lower the cargo vertically. There are many types of davit cranes from all steel stationary davits to portable units made from advanced composite materials. A davit crane is composed of a pedestal or socket base, a frame, and a winch also available as complete units.

By using a modular base system, one davit crane can service multiple areas. The crane rotates a full 360 degrees on a smooth self-lubricating bushing. This is in combination with an external handle ensuring that loads are easily and safely controlled. Further load control is enabled by the rear mounted ratchet screw jack. This allows the angle of the davit crane to be adjusted under full load to provide precise load control.

Contact us for more information about our material lifting equipment or if you have questions or need assistance in selecting a material lifting product.